Why you can trust Tom’s Hardware

Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

The LaserPecker LX2 is a large-format, fully enclosed laser that pairs a swappable 40W diode for cutting with a 2W IR module for fine metal etching. Unlike LaserPecker’s previous portable engravers, the LX2 uses a gantry-style motion system that rides on X-Y rails much like a 3D printer, giving it a generous 500 × 305 mm work area.

It has a speedy motion system that can hit 1000mm/s to produce work quickly. It has both a camera and a probe for automatic positioning and focusing, however our beta unit still needed a bit of refinement. Hopefully these bugs have been worked out for the retail version.

Thanks to its modular design, you can customize the system to suit your needs and budget. Bundles start at $1,649 with a 20W laser and go up to $2,999 for the 40W version with the rotary extension and smoke purifier. The IR module costs an additional $599, and a 60W laser upgrade adds $1,699 if you need extra power. The LX2 is a good laser overall, but it falls just short of being one of the best laser cutters we’ve tested.

Specifications: LaserPecker LX2

|

Machine Footprint |

779.5 x 609.2 x 281.15 mm (30.69 x 23.98 x 11.07 inches) |

Row 0 – Cell 2 |

|

Engraving Size |

500 x 305 (19.7 x 12 inches) |

Row 1 – Cell 2 |

|

Material |

Stainless Steel, Aluminum, Brass, Silver, Plastic, Platinum, Titanium, Wood, Acrylic, Leather, Glass, Rock, Paper, Rubber |

Row 2 – Cell 2 |

|

Laser Type |

Blue Diode, IR |

Row 3 – Cell 2 |

|

Laser Power |

40W diode and 2W IR |

Row 4 – Cell 2 |

|

Max Working Speed |

1000mm/s speed + 10,000mm/s² acceleration |

Row 5 – Cell 2 |

|

Cutting Platform |

Metal slats and baseplate included |

Row 6 – Cell 2 |

|

Connectivity |

USB, Wi-Fi |

Row 7 – Cell 2 |

|

Interface |

Button with LED indicator |

Row 8 – Cell 2 |

|

Supported Software |

LaserPecker Design Space APP & PC Software & LightBurn |

Row 9 – Cell 2 |

|

MSRP |

$1,649 to $1,999 |

Row 10 – Cell 2 |

|

Release Date |

September 2025 (pre-order) |

Row 11 – Cell 2 |

LaserPecker LX2: Included in the Box

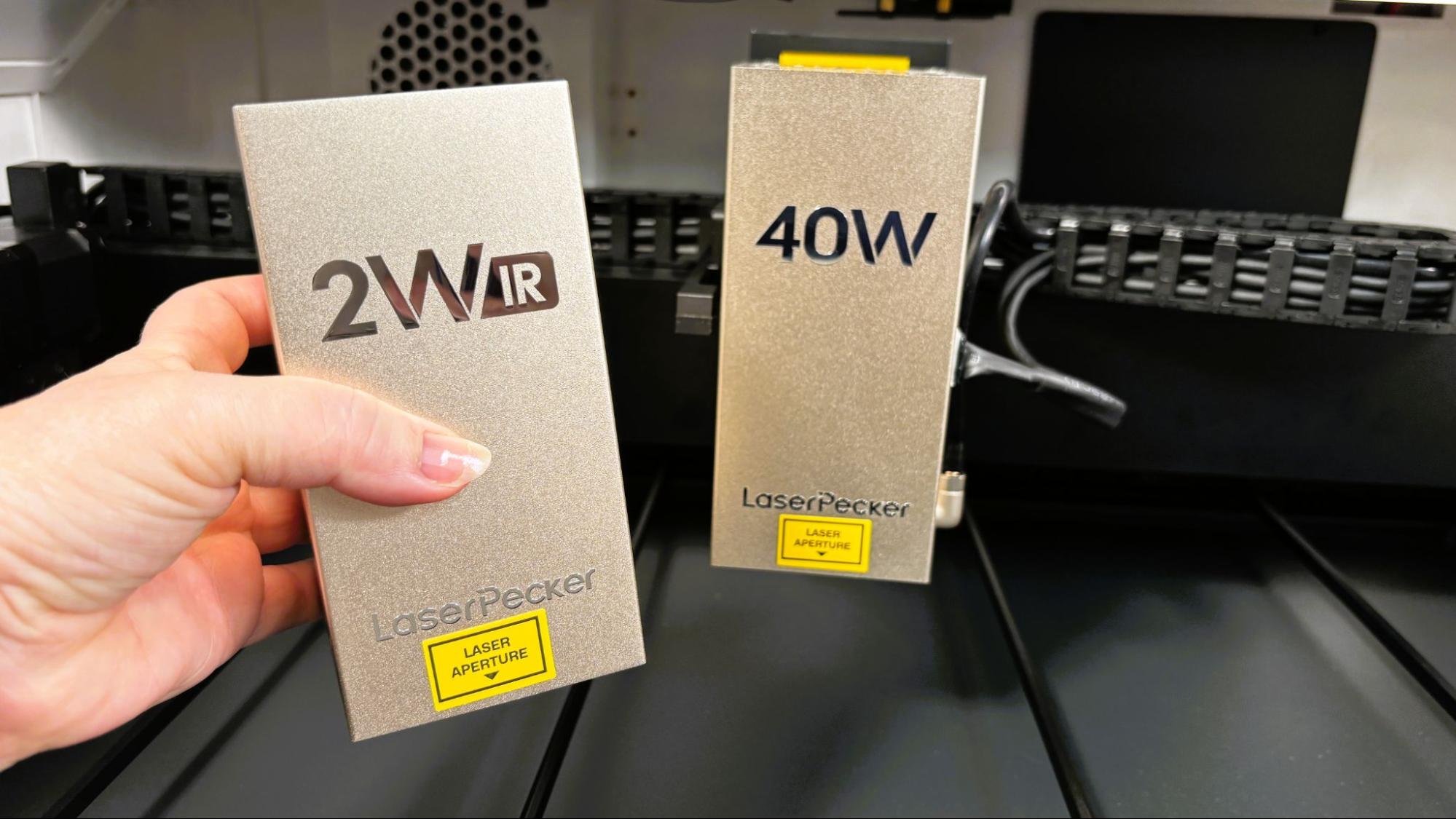

The LaserPecker LX2 Comes nicely packaged in one box. The laser heads, air assist, cutting slats, fire extinguisher, tool kit, manuals, and a small starter pack of materials are packed in foam inside the laser. For the review, we also received the optional 2W IR laser, smoke purifier, riser base, and rotary extension.

Design of the LaserPecker LX2

The LX2 is a fully enclosed Class 1 laser with several interchangeable laser heads to choose from. The unit we received came with a 40W diode and 2W IR laser. LaserPecker also has a 20W diode available now, and a 60W diode which will be available in the future. The laser heads slot into the XY carriage without tools and have one cable to attach plus the air assist tube. On the left side of the head there are magnets to attach the mechanical height probe.

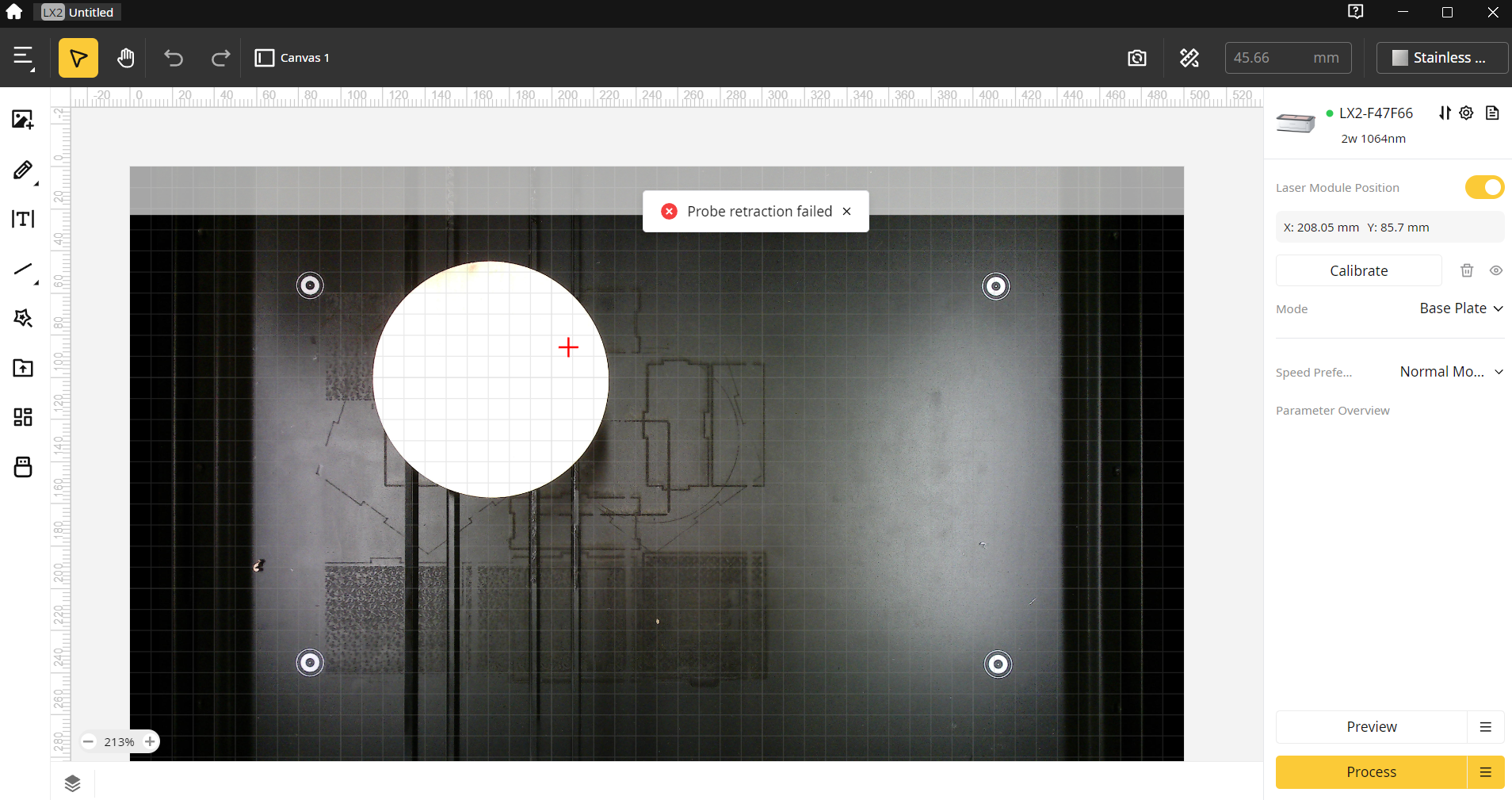

Unfortunately, while the mechanical probe will almost always measure distance correctly and then retract, our test unit was buggy and would not recognize that the probe had retracted. It would then throw a “probe retraction failed” error, which we could ignore after verifying the probe actually retracted. We were able to work around it for most cases, but we could not fully test out LaserPecker’s ability to probe a curved surface.

The X and Y axis of the motion system run on beefy linear rails. The laser tool head can automatically raise and lower to focus, or work with taller items. The work area is well lit with LED lights mounted to the left and right at the top of the compartment. An additional light is mounted on the lid with the positioning camera.

The camera calibration routine is fairly straight forward, but the calibration was inconsistent. It took at least ten tries to get the calibration within a few millimeters of correct. The picture below shows the actual engraving vs where the laser thought it was engraving. You might be able to work around this for larger stock, but for small items like jewelry, this is unacceptable.

The positioning preview mode moves the laser tool head at high speed in order to trace the cutting are with the visible crosshairs. While this is very precise, It’s nearly impossible to nudge items under the flying tool head without getting your hands whacked. Instead, you have to stop the preview, move the item, and start the preview again. This preview method may have worked with LaserPecker’s other lasers – all galvos – but it is irksome on a large gantry mounted laser.

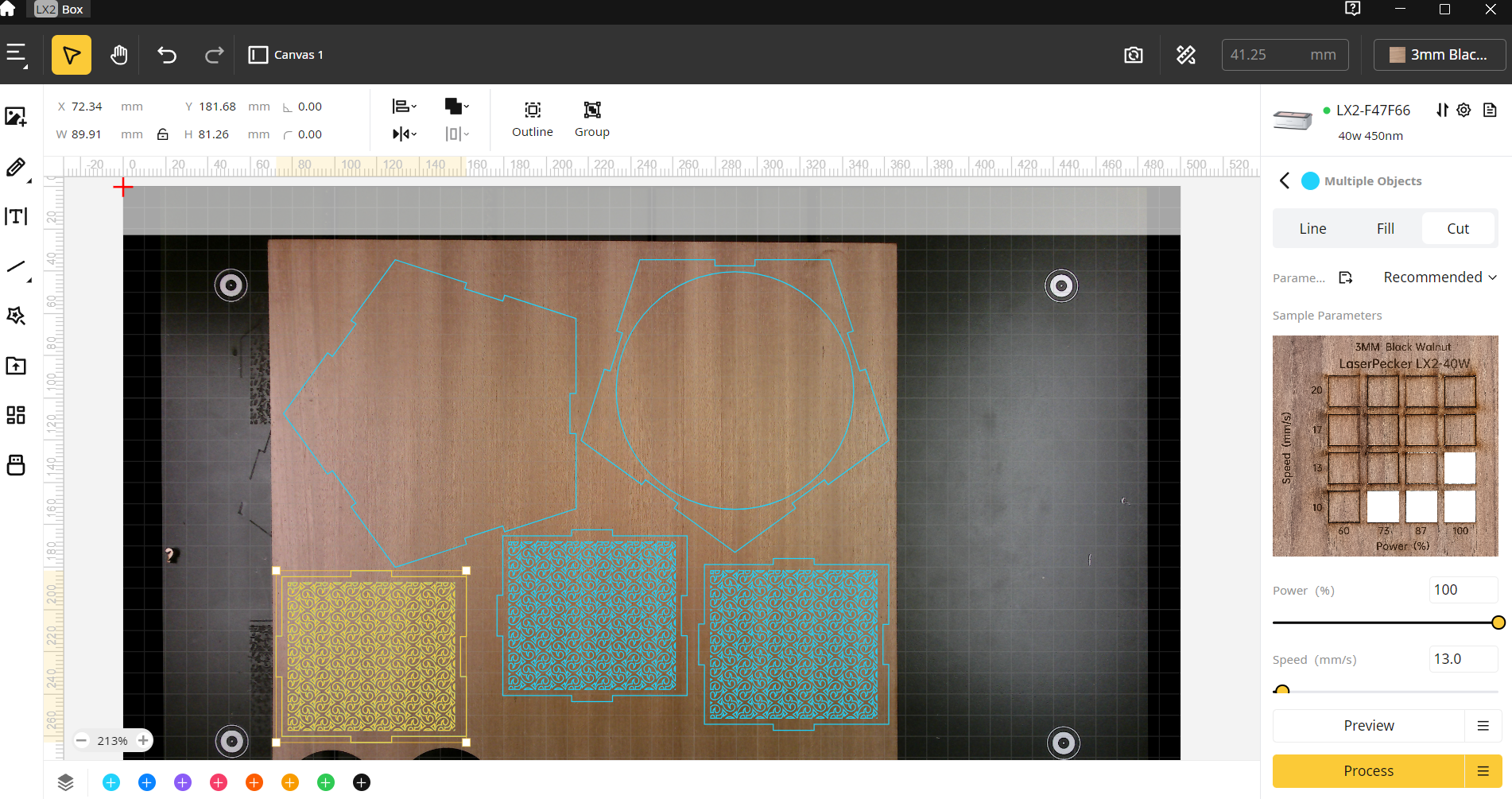

For engraving, items can be placed directly on the base plate. For cutting, there are four slats you fit into slots above the base. This allows air to flow underneath the stock to prevent scorching. It would be helpful if more slats were included.

The unit has a powerful fan to clear smoke from the work area, which is fine if you can vent it to the outside. Otherwise, you will also need a fume extractor or smoke purifier for safety. We used the optional LaserPecker Smoke Purifier, which cut the smoke down to just a whiff of that campfire smell.

The LX2 does not have a screen and must be used with a PC or laptop. The only control is single button with a surrounding LED halo indicator light, showing the laser’s state based on color. There is also a large red emergency stop button on the unit’s right-hand side.

The included air assist plugs into a port on the back of the laser, and is controlled by a single cable. The air assist worked great at limiting charring on deep cuts.

Assembling the LaserPecker LX2

The LaserPecker LX2 is fully assembled from the factory. Set up requires removing foam and a couple zip ties used in shipping. The laser module slots into the XY carriage and is locked into place with a lever. There is one cable and the air assist hose to connect, and that’s it.

All the cables and the equipment key plug into the rear of the unit along with the exhaust hose.

Safety Precautions for the LaserPecker LX2

While there are risks inherent in any laser cutter and engraver, the LaserPecker LX2 is a very safe Class 1 laser. The lid, front panel, and even the riser base doors will stop the laser if they are opened while a job is in process. There is no way to disable this safety feature in the software. Since the laser is literally burning material, never allow it to operate unattended and have a fire extinguisher handy just in case. The unit has flame sensors which are a little too sensitive when set to the default high sensitivity and perfect when set to low sensitivity. Unfortunately, while the task can be restarted after the unit is shut down due to sensing flame, the results were not good, with the laser skipping large areas when reset.

LaserPecker includes an S-type, strontium nitrate and potassium nitrate based fire extinguishing set with two extinguishers in all of its bundles, which is nice. Other companies usually charge extra for this.

Some materials should not be burned with a laser due to their chemical makeup – they could melt, catch fire or produce toxic fumes. Dallas Maker Space has published a list of safe and hazardous materials to use with their laser. The list of no-nos includes plastics, fiberglass and certain foams.

Software for LaserPecker LX2

LaserPecker Design Space is included free and is quite good. It allows easy import of a wide variety of common file types like bitmaps, jpegs and png files. It is easy to add text or clip art and add outlines for cutting or engraving.

Preset material settings are mostly spot on, they aren’t quite as inclusive as I’d like. Cutting something not listed in the presets requires a bit of guestimation which can lead to incomplete cuts or a charred mess.

The LX2 is also compatible with LightBurn, which is a premium program in wide use across the industry.

Engraving / Cutting with the LaserPecker LX2

I dove into the deep end on the first test and tried to cut through, then engrave a piece of 20mm pine. Using the 40W diode laser and guessing on the settings, I first tried to cut out a heart shape I found on LaserPecker Design Space. I used 100% power at 12 mm/s for 3 passes. This did not make it through the material. Bumping the passes up to 6 produced an excellent through cut with almost no charring and very little residue in just over a minute.

Next, I uploaded the Freestar Collective emblem from Starfield as a jpeg to engrave, and added a square cut line from the software. The engraving only took a little over 3 minutes at 50% power and 74 mm/s. The air assist did an excellent job with keeping these cuts clean.

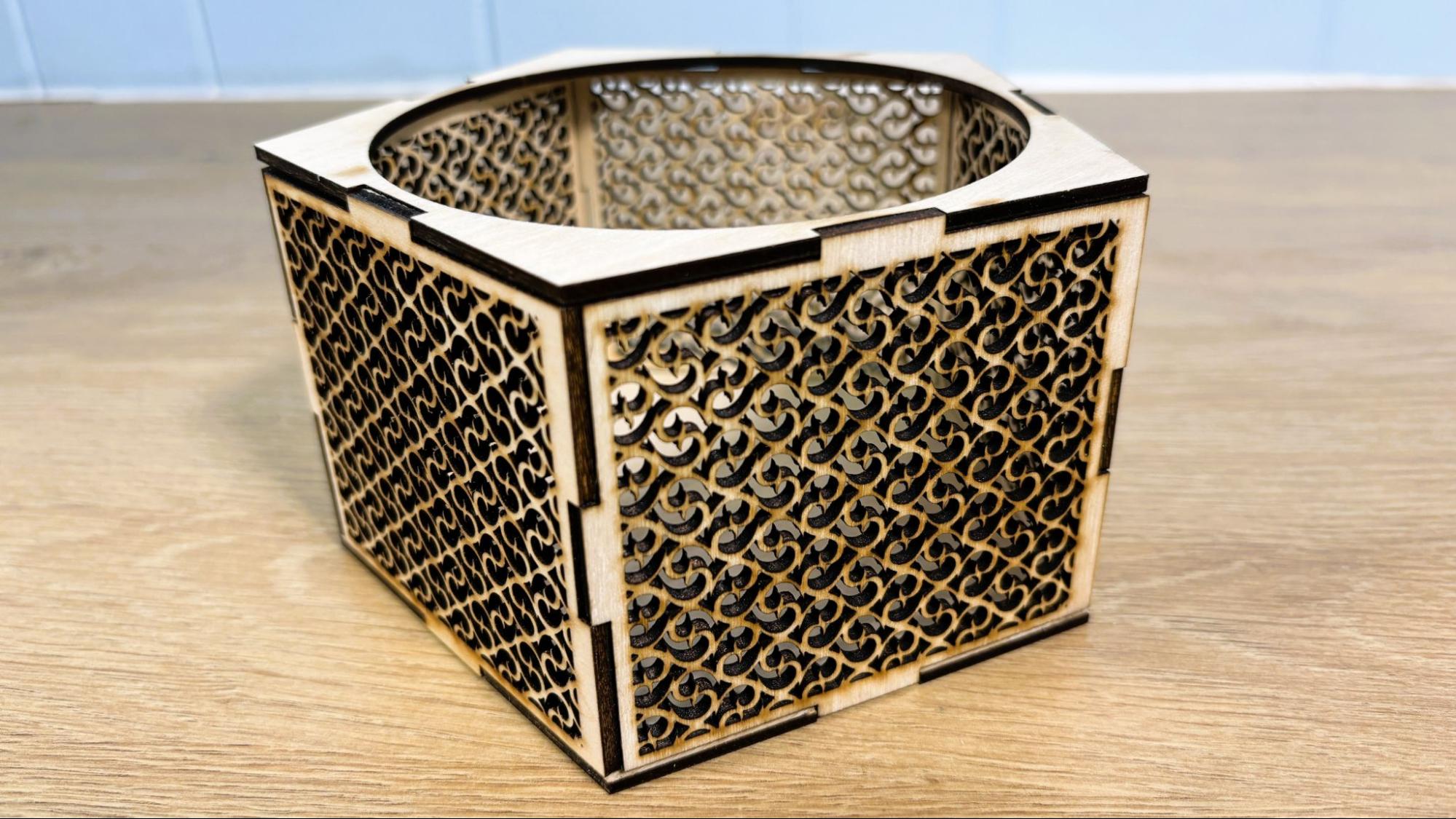

Next, I gave it a more elaborate project using the box generator from Atomm.com. I used 3 mm bass plywood for the material and cutting with 83% power at 16 mm/s the long line cuts were very clean with some of the filigree work needing a fair amount of weeding. A little less speed or a second pass would’ve been perfect. I spread the parts out over two cuts and the processing took a bit under an hour for the whole thing. By the time both were done my workshop had a bit of a campfire smell, despite using the air purifier.

The 40W diode laser did a great job on 3mm opaque acrylic. Using the material presets of 80% power and 7 mm/s for the cuts and 30% power at 212 mm/s for the line engraving, this piece took a little over 4 minutes to complete. Everything came apart cleanly except the smallest interior cuts which got a little melty.

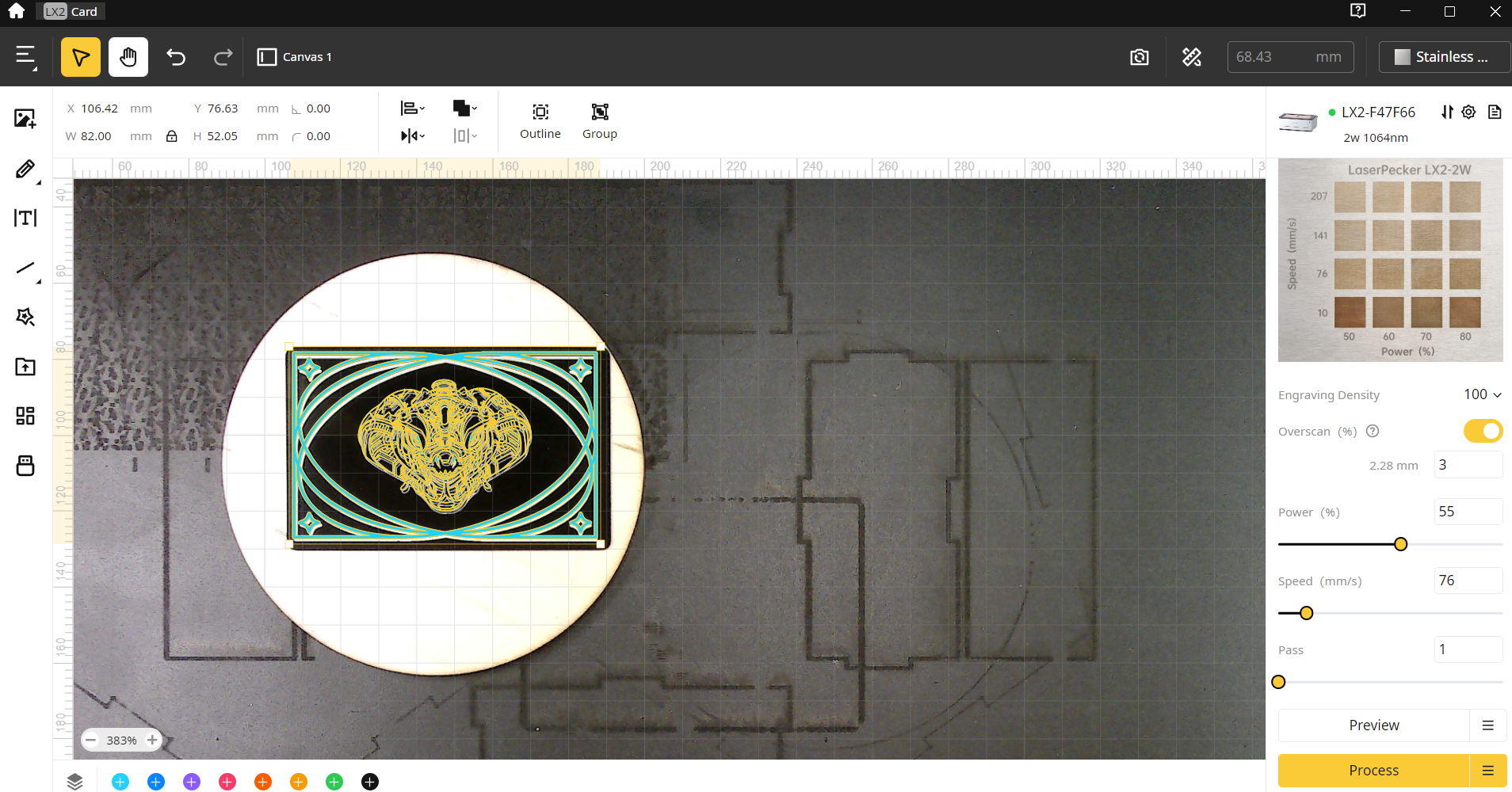

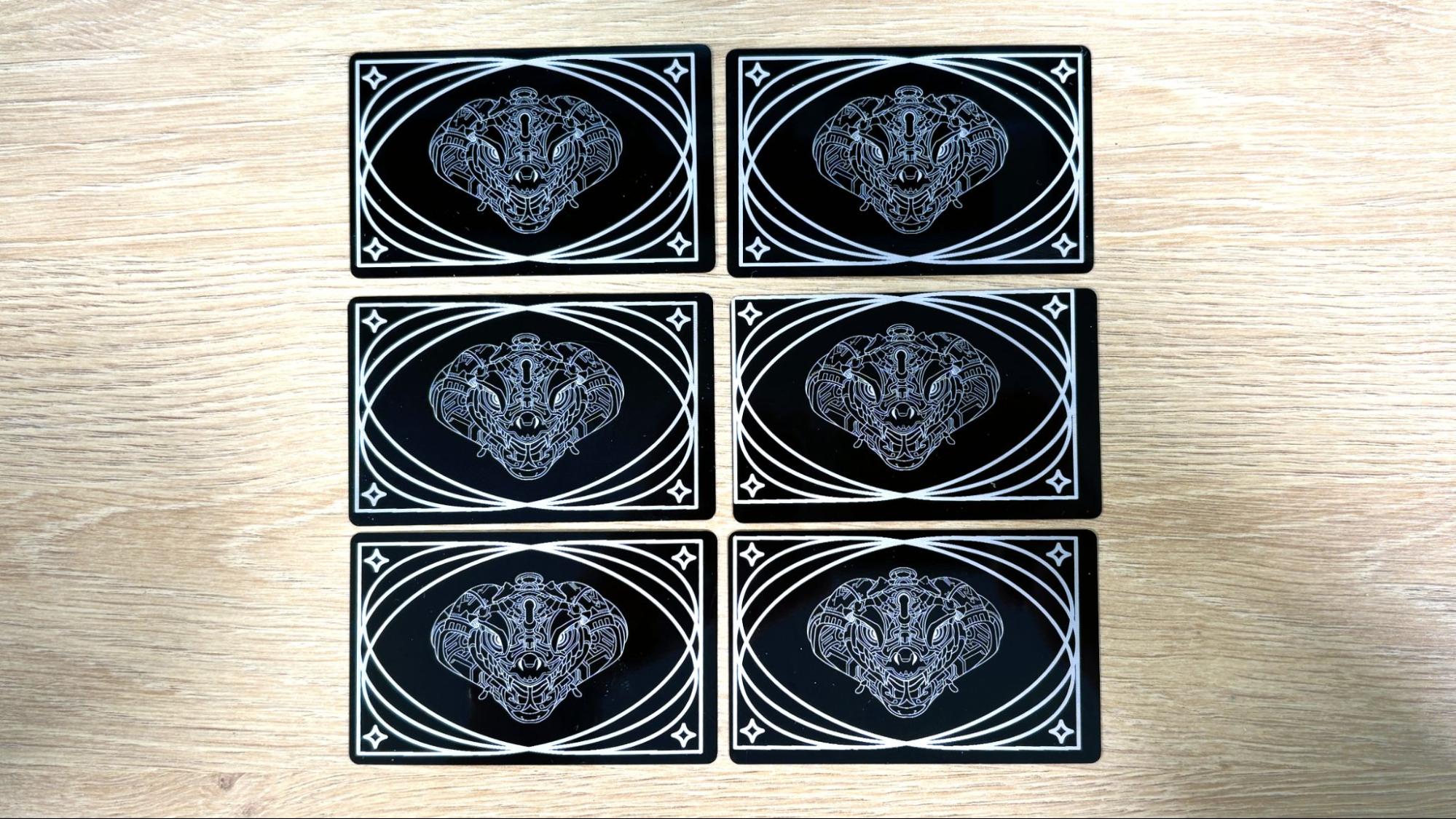

The 2W IR laser produced excellent results on bare and painted metal. I ran a test with clip art from the LaserPecker software to make a design that would go nearly edge to edge on black aluminum business card blanks. The engraving is beautiful, but I was unable to get the art centered on the piece. Each card took a little over 9 minutes at 50% power and 75 mm/s speed.

The 2W IR Laser produced a nice dark engraving on unpainted stainless steel. I used 80% power and 76 mm/s speed. This is more clip art from LaserPecker Design Space, and took a little under 5 minutes to complete.

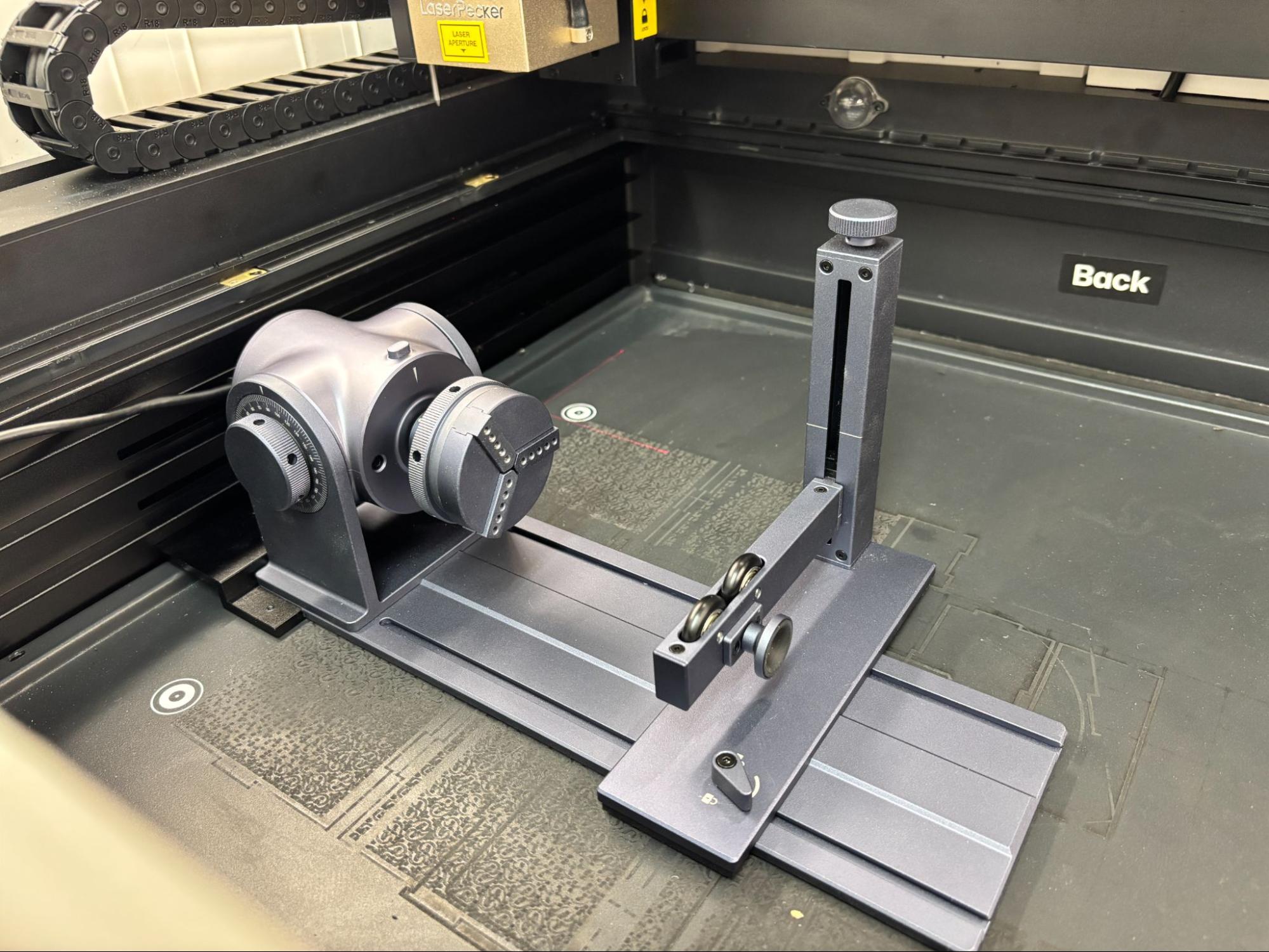

I tested out the optional rotary tool which requires the riser base and moving the build tray to its lowest level. The rotary tool is attached without tools and has a USB cable to attach to the front of the laser.

LaserPecker included a tape measure to measure the circumference of the item to be engraved. The software does an excellent job letting you know where the design will be placed. I used clip art and text from Canva brought into LaserPecker Design Space as a PNG file. I wasn’t sure how the IR laser would handle the clip art, but using the material setting defaults of 20% power and 80 mm/s with Stucki image mode the result is really nice. Any resemblance between the clipart and your humble reviewer is purely coincidental.

Bottom Line

The LaserPecker LX2 gets the fundamentals right. Its enclosed design, large workspace, and powerful laser modules make it far more capable than the company’s earlier portable engravers. The 40W diode delivers fast, confident cutting, while the 2W IR laser adds excellent metal etching, giving the LX2 real versatility for makers who want one machine that can handle both production cuts and detailed finishing work. Add the rotary attachment and optional upgrades, and it feels like a system you can grow into as your budget allows.

The LX2 stumbles in precision and polish. The camera-based positioning isn’t consistent enough to fully trust on small or detailed jobs, and the mechanical probe threw enough false warnings during testing to cause frustration. These are more software than hardware problems, which shouldn’t be difficult to fix. At this price, reliability matters just as much as raw power.

If LaserPecker tightens up the firmware and improves positioning accuracy, the LX2 could be a real showstopper for home workshops and small businesses. As it stands, it’s still a strong performer with excellent cutting and engraving results, but buyers should expect a bit of trial and error. Tinkerers and experienced makers will appreciate its capabilities, while beginners may want to wait for those refinements before diving in.

Thankfully, there are a lot of lasers on the market these days. If you want something safe and portable for taking to events, the xTool F1 is $1099 and packs a punch with a 10w diode and 2W IR. The WeCreat Vision Pro is a similarly sized 45W diode laser that handles most small business cutting needs and can be yours for $1999.

التعليقات